New products:

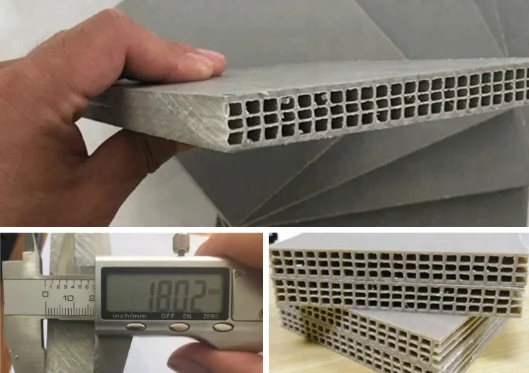

Hollow plastic building templates construction formwork

special specifications can be customized according to customer requirements.

A more scientific design: The supporting points we added are three times more than before. Thus formwork will undertake more pressure and be more firm. Surface of the template is right-angle processed and thicker, bringing more convenience to construction.

New Material-----supporting materials to Value Engineering

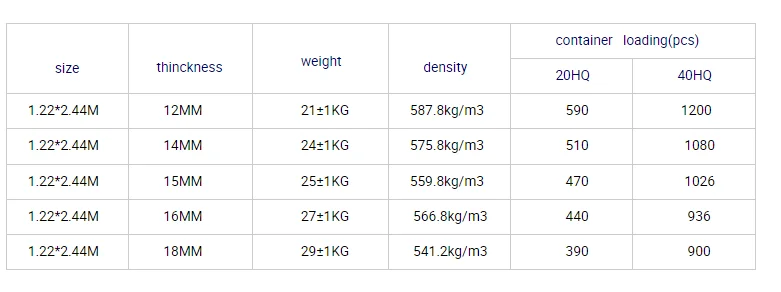

thickness | size | weight |

15mm | 915*1830mm | 11-13kg |

15mm | 1220*2440mm | 19-21kg |

18mm | 915*1830mm | 12-14kg |

18mm | 1220*2440mm | 24-26kg |

Can custom size as customer’s request | ||

Item | plastic formwork |

Size | 1220*2440mm 1830*915mm(can be customized) |

Colors | White ,grey, black |

Feature | Good surface brightness ,no crack |

Excellent strength and toughness performance | |

Non absorbent | |

No deformation, good abrasion resistance | |

Standard size ,reusable | |

Application | Construction industry and bridge-building industry |

market analysis

Plastic and steel, wood and cement are collectively called the four building materials.

Building formwork market demand is increasing year by year, every year nearly 220 million square meters of bamboo/wood production.

Because of shortage of wood source, lumbering trees lead to import timber price rising.

At the same time, the wooden formwork is not recycled, formed a large waste and investment of construction.

plastic template is a kind of energy-saving and green environmental protection products.

Replace of traditional steel template and pine wood template, the amortization cost is low.

Building templates-plastic instead of wood

In recent years, plastic building formwork in foreign develops very fast and more and more varieties,

is widely used in construction project and bridge project, has obtained the good effect;

plastic template is a renewable green environmental protection energy-saving products,

both satisfy the requirement of the construction technology, improve reuse times,

save the wood source and reduce the investment, the use of the company have a major positive.

General Operation And Note Of Instrument For Concrete Formworks

1.Method of use as well as wooden formwork, hollow plastic formwork reinforcement direction with batten direction placed In cross shaped.

2.No need to smear the mold release agent before using formwork.

3.When cast-in-place the flat plate, spacing between the keels should be 20 ~ 25 cm, and the spacing between the wall plate and keel should be 10 ~ 20 cm.

4.The seam-line between templates should be taped.

5.The length of nail should not be too long,generally about 30-35mm.

6.The strength to drive nails should be moderate.

7.When removing the formwork, should start from the small part of one end, the support and the plates should be removed at the same time aiming at preventing the formwork widespread drops,don't let the corner drop on the ground vertically.

8.The formwork accesses to be mixed used with wood plywood formwork,bamboo formwork and other material formwork